Public innovation has reached an inflection point. Nowhere is this clearer than in Europe, where concerns mount about the growing innovation gap with the US and China. This gap exists despite more spending per GDP on public research, a high world share of scientific publications and a strong position in patenting according to the European Commission’s 2024 Draghi Report. Innovators are producing world-class knowledge, but much of it stays within academic circles, never progressing toward application or impact.

"Much of the knowledge generated in research institutions remains commercially unexploited. According to the European Patent Office (EPO), only about one-third of the patented inventions registered by European universities or RTOs are commercially exploited."

- The Future of European Competitiveness (Draghi Report)

The challenge facing Europe today is strikingly similar to what once plagued manufacturing, startups, and software development: slow progress, underused talent, and fragmented systems. In each case, the solution was a shift from maximizing output to maximizing learning and value, driven by feedback, iteration, and real-world responsiveness.

This transformation was guided by Lean Thinking.

Lean Thinking

Lean Thinking began in post-WWII Japan, when Toyota pioneered methods for eliminating waste, improving flow, and empowering workers to improve quality and efficiency. These principles went on to revolutionize manufacturing, shape Agile and DevOps in software, guide startups through Lean Startup methodology, and inspire mission-driven organizations through Lean Impact.

While not every Lean domain shares all the same constraints, each faced persistent friction caused by complexity, uncertainty, or institutional inertia, making traditional, linear approaches inefficient. That’s where Lean made the difference: by creating systems that could learn and adapt quickly. The application of Lean Thinking to social change is a testament to its applicability to mission- and knowledge-driven domains.

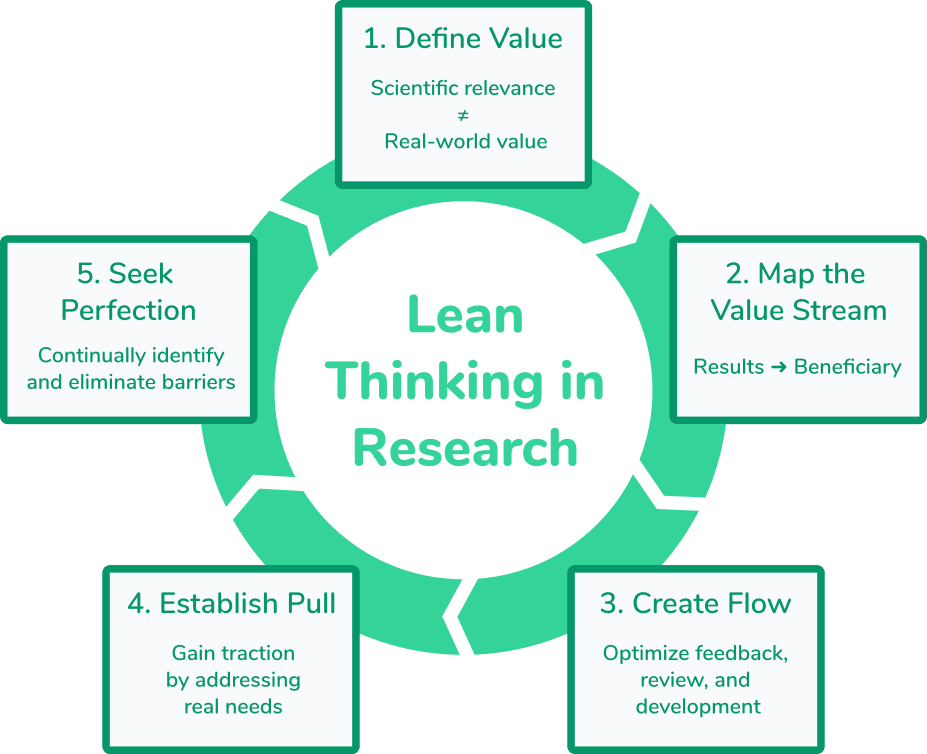

Lean Thinking is structured around five principles (illustrated below).

The next section explores what these principles mean for companies, innovators, and teams seeking to improve efficiency, relevance, and real-world impact—especially for ideas that aim to reach markets, public services, or societal goals.

Lean Principles in Innovation

Lean Thinking can play a role in innovation initiatives that often diverge from real-world use, not for lack of quality, but because of misalignment between what is created and what the world actually needs. Lean helps teams make better strategic decisions earlier, shaping work that is robust, useful, fundable, and scalable.

The core Lean principles can bring agility, focus, and stakeholder alignment to the innovation process. Each principle is described below in an innovation context.

Define Value

Creating value from innovation (referred to as valorization in the academic world) can take many forms, including commercialization, citizen participation, policy influence, open science, cultural or educational outreach, and practical implementation.

It is crucial to clarify which forms of value the work could realistically support, and which stakeholders might care. Many projects stall because they pursue technically elegant work that lacks a clear beneficiary who is willing and motivated to integrate the innovation into their workflow.

Academic KPIs can be deceiving

Traditional academic metrics (like publication count, journal impact factor, or citation rates) reward novelty and theoretical rigor, not real-world applicability. When defining value, it’s critical to look beyond common academic KPI's and consider what will matter to beneficiaries, practitioners, or policy makers.

Map the Value Stream

The term value stream describes the steps that turn an idea into a meaningful outcome, such as improving patient care, enabling policy, or creating a viable product. In innovation ecosystems, one of the most common tools for describing technological maturity is the Technology Readiness Level (TRL) scale, which ranks maturity from 1 (basic principles observed) to 9 (proven in operational environment). But real-world innovation is rarely linear. Promising ideas often stall in the “valley of death” where funding ends, regulations pose challenges, or assumptions remain untested.

Key questions for mapping the value stream include:

- What conditions must hold true for this to work in practice?

- Who would benefit—and under what constraints?

- What bridges are missing between our current work and future use?

Create Flow

Flow is the continuous and efficient progression of value through a process, minimizing delays, waste, and interruptions. In innovation, this means reducing delays between insight, feedback, and decision-making and working across silos, which ultimately translates to higher quality, greater relevance, and genuine morale.

To improve flow, innovation teams can:

- Shorten feedback loops with potential users or clinical stakeholders

- Integrate ethical and regulatory perspectives early, avoiding rework down the road

- Break big questions into testable components to maintain direction and flexibility

- Design projects to surface uncertainty early, not hide it until late stages

- Write agility into grant proposals, ensuring projects are adaptive and iterative

Establish Pull

Pull means responding to real demand rather than pushing ideas forward based solely on internal priorities. In Lean Thinking, establishing pull ensures that effort is directed toward outcomes that are actually needed and likely to be adopted.

In academic research, "pull" is often interpreted through proxies like scientific curiosity, citation potential, or available grant calls. While valid within the academic system, these signals don’t always reflect unmet needs in practice, policy, or industry.

To establish true pull, innovators should explore:

- Who would actively want or use this innovation, and why?

- What barriers do potential adopters face in integrating new solutions?

- Are there stakeholders signaling urgency or readiness, beyond academic circles?

Working toward pull doesn’t mean abandoning fundamental research. It means spotting opportunities for real-world relevance and measuring early traction as a signal that the work aligns with genuine demand.

Seek Perfection

Seeking perfection in Lean doesn’t mean flawless outputs. It means continuously improving the process by identifying friction, learning faster, and aligning efforts with purpose.

In innovation, this mindset shifts focus from polishing individual results to improving the system of inquiry:

- Are we working on the right problems?

- Are we learning fast enough to make informed decisions?

- Are we spending time on questions unlikely to lead to meaningful outcomes?

Perfection is pursued not through control, but through reflection, feedback, and refinement.

Ready to Make Your Innovation Go Further?

Whether you are leading an innovation team or supporting one, you're likely already doing valuable, rigorous work. If you're aiming to boost real-world relevance, speed up progress, or strengthen your team's impact, then get in touch with Eunovus.